Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 22, 2024 Visit:420 Source:Roll Forming Machine Factory

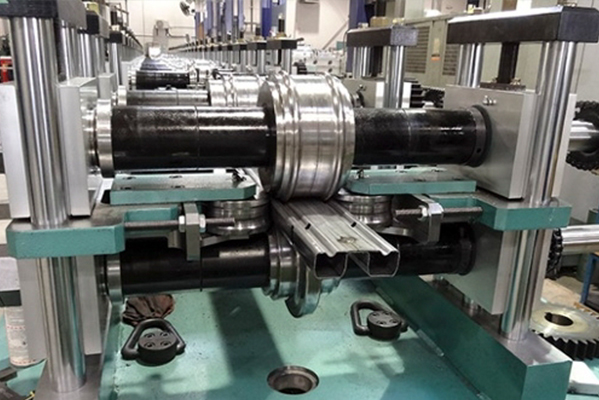

The versatility and efficiency of roll forming machines have led to their increasing adoption across a wide range of industries. These machines, which shape materials into desired profiles through a series of rolls, are finding new applications in various sectors, from automotive and aerospace to construction and furniture.

In the automotive industry, roll forming machines are playing a pivotal role in the production of structural components such as frames, beams, and other parts. The precision and repeatability of roll forming enable manufacturers to produce parts that meet strict tolerance requirements, ensuring the safety and performance of vehicles. As the automotive industry continues to evolve, with a focus on lighter materials and increased fuel efficiency, roll forming machines are becoming even more critical in enabling these advancements.

The aerospace industry, known for its demanding specifications and strict regulations, also benefits from roll forming technology. Components like aircraft fuselage sections, wing structures, and landing gear require high levels of accuracy and strength. Roll forming machines can produce these parts with the necessary precision, reducing the need for secondary operations and ensuring consistency in quality.

The construction industry has also seen a surge in the use of roll forming machines. Steel and aluminum beams, pipes, and other structural elements are essential in the construction of buildings, bridges, and infrastructure projects. Roll forming machines can produce these elements in various sizes and shapes, enabling construction companies to tailor their materials to specific project needs. This flexibility, combined with the high-speed production capabilities of roll forming machines, helps to keep construction timelines on track and costs under control.

In the furniture industry, roll forming machines are used to create frames, legs, and other components for chairs, tables, and other furniture items. The ability to produce these parts with precise dimensions and smooth finishes makes roll forming an ideal choice for furniture manufacturers looking to improve product quality and aesthetics.

Additionally, roll forming machines are finding applications in other industries such as appliance manufacturing, where they are used to produce parts like refrigerator frames and washing machine drums. In the packaging industry, roll formed materials are used to create shipping containers, display racks, and other packaging solutions.

The expanding applications of roll forming machines are driven by several factors. Firstly, the technology continues to evolve, with advancements in automation, materials, and software making roll forming machines more capable and efficient. Secondly, the demand for precision-engineered components across diverse industries is increasing, driving the adoption of roll forming as a reliable manufacturing process.

As industries continue to evolve and demand for high-quality, precision-made components grows, the applications of roll forming machines will likely expand further. Manufacturers and engineers are constantly exploring new ways to leverage the capabilities of roll forming machines, pushing the boundaries of what is possible in various sectors.

In conclusion, roll forming machines are becoming indispensable tools in a wide range of industries. Their ability to produce precision-engineered components quickly and efficiently makes them a valuable asset for manufacturers across diverse sectors. As technological advancements continue to drive the capabilities of roll forming machines, their applications will undoubtedly continue to expand, opening up new opportunities for innovation and efficiency in manufacturing.