Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 22, 2024 Visit:395 Source:Roll Forming Machine Factory

The roll forming machine market is experiencing a significant wave of technological advancements that are transforming the manufacturing landscape. These innovations are not only enhancing the capabilities of roll forming machines but also making them more efficient, flexible, and adaptable to diverse industrial needs.

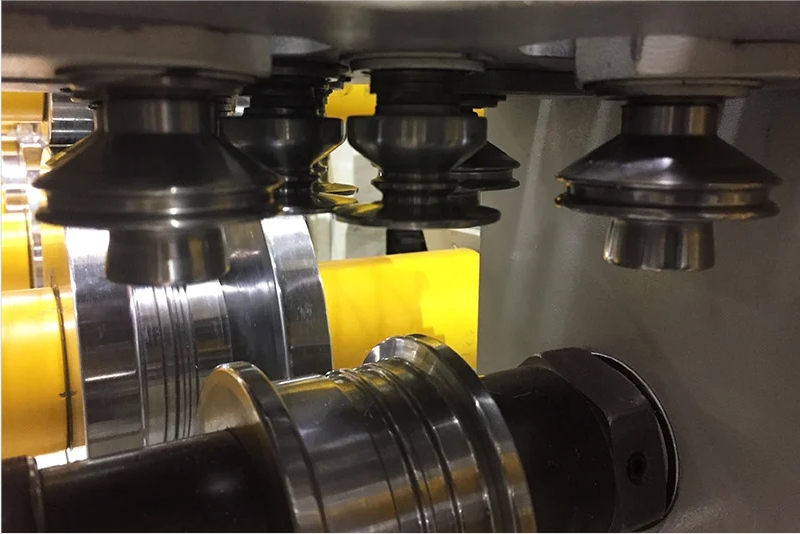

One notable technological advancement is the integration of automation and robotics in roll forming machines. This integration allows for more precise control over the forming process, reducing human error and enhancing product consistency. Automated systems can also optimize production schedules, reducing downtime and increasing overall productivity. Robotics, in particular, are enabling roll forming machines to handle complex shapes and materials with greater ease and accuracy.

Another key technological development is the use of advanced materials in the construction of roll forming machines. These materials, such as high-strength steels and advanced composites, provide enhanced durability and performance. They enable roll forming machines to operate at higher speeds and under more demanding conditions, thus expanding their range of applications.

In terms of software, roll forming machine manufacturers are incorporating advanced algorithms and simulation tools into their design processes. These tools allow for more accurate predictions of material behavior during the forming process, enabling manufacturers to optimize machine settings and reduce waste. Additionally, real-time monitoring and feedback systems are becoming more prevalent, providing operators with immediate insights into machine performance and allowing for quicker adjustments.

The advent of smart manufacturing technologies is also having a profound impact on the roll forming machine market. Smart sensors and IoT (Internet of Things) devices are being integrated into roll forming machines, enabling remote monitoring, predictive maintenance, and real-time data analysis. This connectivity allows manufacturers to gain deeper insights into machine performance and operational efficiency, leading to more informed decision-making and improved overall outcomes.

Moreover, the increasing adoption of additive manufacturing (also known as 3D printing) is influencing the roll forming machine market. While additive manufacturing and roll forming are distinct processes, there are areas where they can complement each other. For instance, 3D printing can be used to create custom tooling and dies for roll forming machines, reducing lead times and enhancing design flexibility.

The integration of AI (Artificial Intelligence) and machine learning is another exciting technological advancement in the roll forming machine market. These technologies are enabling machines to learn from data, optimize processes, and predict outcomes with greater accuracy. AI-driven roll forming machines can adapt to changing conditions in real-time, ensuring consistent product quality and reducing the need for manual intervention.

As these technological advancements continue to unfold, they are creating new opportunities for roll forming machine manufacturers and their customers. Manufacturers can differentiate themselves in the market by offering machines with cutting-edge features and capabilities. Customers, in turn, can benefit from increased productivity, reduced costs, and the ability to tackle more complex manufacturing challenges.

In conclusion, the roll forming machine market is experiencing a period of rapid technological advancement that is transforming the industry. From automation and robotics to advanced materials, smart manufacturing, and AI, these innovations are driving efficiency, flexibility, and innovation in manufacturing processes. As these technologies continue to evolve, they will play an increasingly critical role in shaping the future of the roll forming machine market.