Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 22, 2024 Visit:358 Source:Roll Forming Machine Factory

The manufacturing landscape is constantly evolving, with a focus on improving productivity, reducing costs, and enhancing product quality. In this dynamic environment, roll forming machine manufacturers are playing a pivotal role by developing advanced solutions that significantly enhance production efficiency.

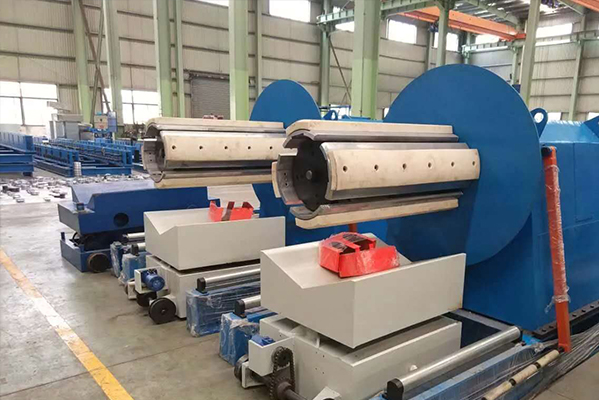

Roll forming machines are designed to shape materials such as steel, aluminum, and other metals into desired profiles through a series of rolls. This process is highly efficient and can produce components with precise dimensions and smooth finishes. Manufacturers of roll forming machines are continuously innovating to improve the performance, reliability, and versatility of these machines, enabling them to meet the ever-changing demands of the manufacturing industry.

One key area of focus for roll forming machine manufacturers is automation. By integrating advanced automation technologies, such as robotics and sensors, manufacturers are able to streamline the production process, reduce human error, and increase output. Automated roll forming machines can operate continuously, with minimal supervision, ensuring that production runs smoothly and efficiently.

Another important aspect of enhancing production efficiency is the optimization of machine design. Roll forming machine manufacturers are constantly refining their designs to improve the machine's ability to handle a wider range of materials and thicknesses. This flexibility allows manufacturers to produce a broader range of components with a single machine, reducing the need for multiple specialized machines and increasing overall production capacity.

In addition to automation and design optimization, roll forming machine manufacturers are also focusing on improving the machine's maintenance and serviceability. By incorporating features such as easy-to-access components and modular designs, manufacturers are making it easier for operators to perform routine maintenance and repairs. This reduces downtime and ensures that machines remain in optimal operating condition, contributing to higher production efficiency.

Furthermore, roll forming machine manufacturers are leveraging advanced software technologies to enhance production efficiency. Software solutions, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), enable manufacturers to design and program roll forming machines with greater precision. This, in turn, leads to improved component accuracy and reduced waste.

The benefits of these advancements are evident across various industries. For example, in the automotive industry, roll forming machines are used to produce structural components such as frames and beams. The enhanced efficiency of these machines allows automakers to increase production volumes while maintaining high-quality standards. Similarly, in the construction industry, roll forming machines are used to produce steel beams and other structural elements. The ability to produce these components quickly and efficiently is crucial for keeping construction projects on schedule and within budget.

In conclusion, roll forming machine manufacturers are playing a crucial role in enhancing production efficiency across diverse industries. By focusing on automation, design optimization, maintenance and serviceability improvements, and advanced software technologies, these manufacturers are driving innovation and progress in the manufacturing sector. As the demand for precision-engineered components continues to grow, the role of roll forming machine manufacturers in enhancing production efficiency will become even more critical.