Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 22, 2024 Visit:358 Source:Roll Forming Machine Factory

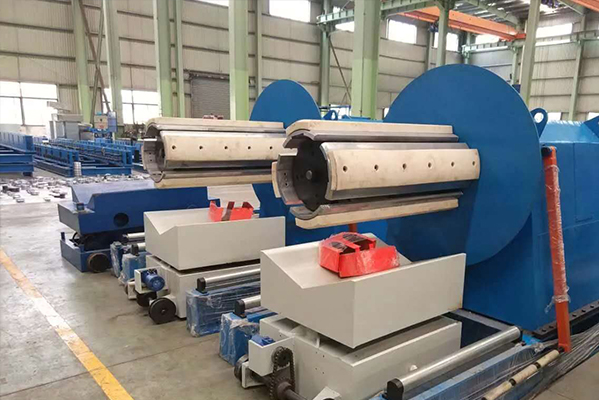

In the realm of manufacturing, the pursuit of excellence in product quality is a relentless endeavor. Among the various technologies driving this pursuit, roll forming machines have emerged as key players, particularly due to the innovative designs that are continually being introduced to enhance their capabilities. These design innovations not only streamline production processes but also significantly improve the quality of the final products.

At the heart of roll forming machine design innovations lies a commitment to precision. Traditional roll forming machines have been known for their ability to shape metal into complex profiles with consistent dimensions. However, modern designs have taken this precision to new heights. Advanced sensors and control systems now allow for real-time monitoring and adjustment of the rolling process, ensuring that even the slightest deviations are corrected immediately. This results in products that meet the tightest tolerances and specifications, meeting or even exceeding customer expectations.

Another significant design innovation in roll forming machines is the integration of flexibility. Traditional machines were often limited to producing a specific range of profiles. However, with the advent of modular and adjustable roll designs, manufacturers can now easily switch between different profiles, accommodating a wider variety of customer needs. This flexibility not only increases production efficiency but also allows for greater customization, leading to higher product quality.

The use of advanced materials in roll forming machine design has also contributed to improved product quality. Traditional materials, such as cast iron and steel, have been replaced with lighter, stronger, and more durable alternatives like high-strength alloys and composites. These materials not only enhance the machine's durability and lifespan but also reduce the risk of wear and tear, which can affect product quality over time.

In addition to material innovations, roll forming machines now incorporate state-of-the-art lubrication systems. These systems ensure that the rolls and other moving parts are always adequately lubricated, reducing friction and wear. This not only extends the machine's lifespan but also ensures that the metal being formed is not damaged during the process, leading to higher product quality.

Furthermore, roll forming machine designers have focused on improving the user interface and control systems. Intuitive touchscreens and user-friendly software have made it easier for operators to control and monitor the machine. This not only reduces the risk of human error but also allows for more precise adjustments to be made during the production process, further enhancing product quality.

These design innovations have had a profound impact on the quality of roll-formed products. In industries such as automotive, aerospace, and construction, where precision and durability are paramount, roll forming machines have become indispensable. The ability to produce complex profiles with tight tolerances, combined with the flexibility to switch between different products, has made roll forming machines a go-to solution for manufacturers seeking to improve their product quality.

In conclusion, roll forming machine design innovations have significantly improved product quality across various manufacturing sectors. From precision and flexibility to advanced materials and lubrication systems, these innovations have set new standards for product excellence. As manufacturers continue to push the boundaries of what is possible, roll forming machines will undoubtedly play a crucial role in driving product quality improvements in the future.