Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:443 Source:Roll Forming Machine Factory

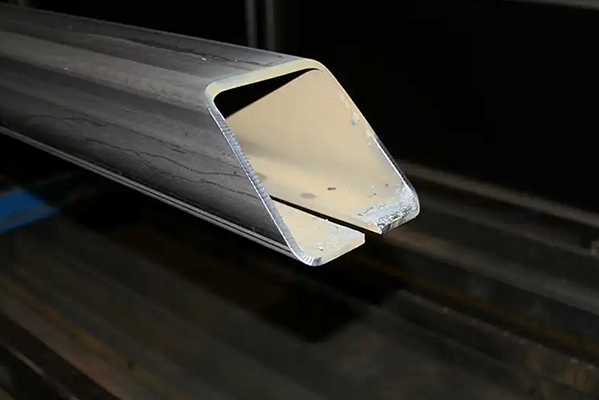

In the realm of manufacturing, the demand for precision, efficiency, and versatility is ever-growing. To meet these demands, the metalworking industry has witnessed a surge in the development of integrated cold forming machine solutions. These solutions are designed to optimize production lines for diverse applications, enhancing productivity, quality, and flexibility across various sectors. This article explores the key features and benefits of integrated cold forming machine solutions and their impact on various manufacturing processes.

Versatile Tooling Systems

One of the hallmarks of integrated cold forming machine solutions is their versatile tooling systems. These systems are engineered to accommodate a wide range of forming operations, including punching, bending, and coining. By utilizing modular and interchangeable tooling components, manufacturers can quickly adapt their production lines to produce different parts and components. This versatility enables companies to meet the demands of diverse applications, from automotive components to electronic parts, without significant retooling or downtime.

Precision and Consistency

Integrated cold forming machines are known for their precision and consistency in producing parts. These machines utilize advanced control systems and sensors to monitor and regulate forming parameters such as force, speed, and temperature. This ensures that each part is formed to exact specifications, reducing waste and enhancing overall quality. Additionally, the precision of these machines allows for tight tolerances and complex geometries, enabling manufacturers to produce high-performance parts that meet the most stringent requirements.

Increased Efficiency and Productivity

By integrating cold forming machines into production lines, manufacturers can significantly increase efficiency and productivity. These machines operate at high speeds, producing parts in rapid succession. Furthermore, their automated nature reduces the need for manual intervention, minimizing human error and labor costs. Integrated solutions often include conveyors and robotic systems that further streamline the production process, ensuring seamless material handling and part transfer.

Scalability and Flexibility

Another advantage of integrated cold forming machine solutions is their scalability and flexibility. These systems can be easily scaled up or down to match production demands. This enables manufacturers to adapt to fluctuating market conditions and customer requirements without significant capital investment. Additionally, the modular design of these solutions allows for easy integration with existing machinery and processes, providing a seamless transition to more advanced manufacturing capabilities.

Enhanced Quality Control

Integrated cold forming machines also offer enhanced quality control features. Many systems include inline inspection and measurement tools that continuously monitor part dimensions and quality. This data is collected and analyzed in real-time, allowing manufacturers to identify and correct any deviations from specifications promptly. Furthermore, the integration of advanced data analytics and machine learning algorithms can predict potential quality issues before they occur, enabling proactive maintenance and process optimization.

Conclusion

In conclusion, integrated cold forming machine solutions are transforming manufacturing processes across diverse applications. Their versatile tooling systems, precision and consistency, increased efficiency and productivity, scalability and flexibility, and enhanced quality control features make them invaluable assets for modern manufacturers. As the demand for high-quality, precision-made parts continues to grow, the adoption of these integrated solutions will be crucial in maintaining a competitive edge in the global manufacturing landscape. By leveraging the latest technology, manufacturers can optimize their production lines, enhance product quality, and drive innovation in their respective industries.