Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 23, 2024 Visit:398 Source:Roll Forming Machine Factory

In the realm of industrial manufacturing, Chinese roll forming machine manufacturers have carved out a niche for themselves by consistently pushing the boundaries of productivity. These manufacturers have become synonymous with precision, reliability, and efficiency, offering a range of roll forming machines tailored to meet the diverse needs of the global market.

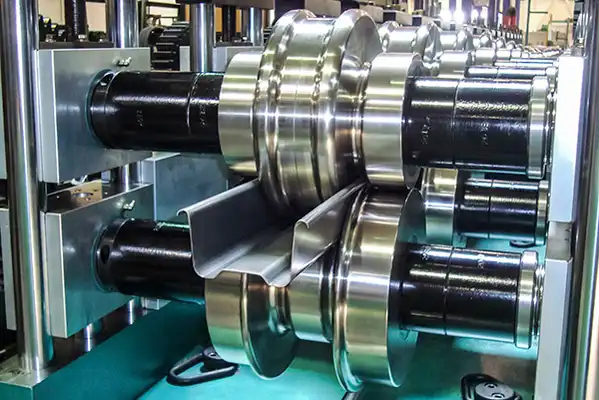

Roll forming is a vital process in the fabrication of numerous products, from metal roofing and automotive parts to structural components and more. It involves the continuous bending of a strip of metal into a desired shape through a series of precision-engineered rolls. The quality and capabilities of the roll forming machines used in this process are crucial in determining the final product's accuracy and efficiency.

Chinese manufacturers have responded to the growing demand for high-productivity roll forming solutions by investing heavily in research and development. They have embraced advanced manufacturing techniques and incorporated cutting-edge technologies into their production processes. This has led to the creation of roll forming machines that are not only more precise and reliable but also capable of operating at faster speeds and with reduced downtime.

One of the key strategies employed by these manufacturers to enhance productivity is the integration of automation and intelligence into their machines. By incorporating sensors, control systems, and data analytics, they have developed machines that can monitor and adjust their operations in real-time. This ensures optimal performance and reduces the risk of errors, thereby increasing overall productivity.

Moreover, Chinese roll forming machine manufacturers have focused on modular and customizable designs. This allows customers to tailor the machines to their specific requirements, optimizing them for different materials, shapes, and production volumes. Such flexibility not only enhances productivity but also supports the development of new products and the adaptation to market changes.

In addition to technological advancements, Chinese manufacturers have also emphasized the importance of after-sales support and services. They offer comprehensive training programs for operators and maintenance personnel, ensuring that their customers can fully utilize the capabilities of their machines. Furthermore, they provide timely maintenance and repairs, minimizing unexpected downtimes and maintaining the productivity of the manufacturing processes.

The dedication to enhancing productivity extends beyond the machines themselves. Chinese roll forming machine manufacturers have also focused on optimizing the entire production workflow. This includes improving material handling, streamlining logistics, and integrating roll forming processes with other manufacturing steps. By creating seamless and efficient workflows, they have enabled their customers to achieve higher levels of productivity and competitiveness.

Furthermore, Chinese manufacturers have established strong partnerships with suppliers and customers, fostering collaboration and innovation. This collaborative approach has led to the development of new materials, technologies, and processes that further enhance productivity. By working together, these manufacturers have been able to address challenges and seize opportunities in the rapidly evolving manufacturing landscape.

In conclusion, Chinese roll forming machine manufacturers have demonstrated a remarkable commitment to enhancing productivity. Through continuous innovation, adoption of advanced technologies, and focus on customer support and workflow optimization, they have positioned themselves as leaders in the industry. As the manufacturing landscape continues to evolve, these manufacturers are poised to play an even more significant role in driving productivity and innovation forward.