Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 13, 2024 Visit:459 Source:Roll Forming Machine Factory

In the ever-evolving landscape of the manufacturing industry, trends and demands often shift, presenting both challenges and opportunities for businesses. Recently, a prominent roll forming machine importer has observed a notable increase in demand from the automotive sector. This surge in interest underscores the growing importance of roll forming technology in the production of automotive components and highlights the evolving needs of the industry.

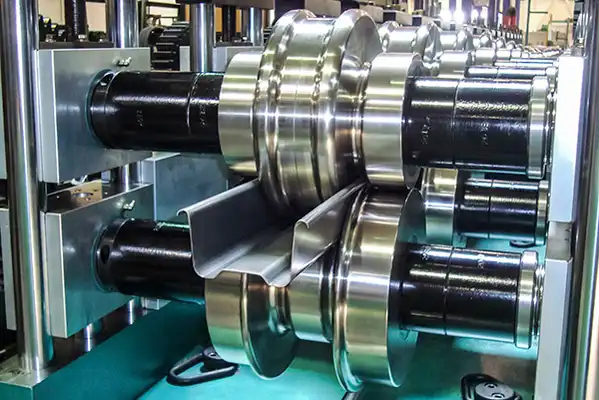

Roll forming machines are known for their precision and efficiency in shaping metal into various profiles and sections. In the automotive sector, these machines are particularly valuable for the production of structural components such as frame rails, roof rails, and door beams. The ability to create complex shapes with high accuracy and consistency makes roll forming an ideal process for meeting the stringent quality standards of the automotive industry.

The importer, which has been serving the manufacturing community for several years, has noticed a significant rise in inquiries and orders related to roll forming machines tailored for automotive applications. This increase in demand can be attributed to several factors. Firstly, the automotive industry is undergoing a period of rapid innovation, with manufacturers constantly seeking ways to enhance the performance, safety, and fuel efficiency of their vehicles. Roll forming machines play a crucial role in this pursuit by enabling the production of lightweight yet strong components that contribute to these improvements.

Secondly, the global automotive market is expanding, with emerging economies driving growth in vehicle sales. This expansion has led to an increased demand for automotive components, including those produced through roll forming. Manufacturers are looking to scale up their production capabilities to meet this demand, and roll forming machines offer a scalable and efficient solution.

Moreover, the automotive industry's focus on cost optimization has also contributed to the increased demand for roll forming machines. By automating the shaping process, these machines reduce labor costs and increase production speeds, making them an attractive option for manufacturers seeking to improve their bottom line.

In response to this growing demand, the roll forming machine importer has taken several steps to ensure it can meet the needs of the automotive sector. It has expanded its inventory to include a wider range of machines specifically designed for automotive applications, ensuring that customers can find the right equipment for their production requirements. Additionally, the importer has invested in enhancing its customer service and technical support capabilities, providing training and troubleshooting assistance to ensure that automotive manufacturers can maximize the performance of their roll forming machines.

The importer has also been actively engaging with automotive manufacturers to understand their unique challenges and requirements. This collaboration has led to the development of customized solutions that address specific production needs, further strengthening the importer's position as a trusted partner in the automotive sector.

In conclusion, the increased demand for roll forming machines in the automotive sector reflects the industry's evolving needs and the growing importance of precision manufacturing. By adapting to these changes and offering tailored solutions, the roll forming machine importer is well-positioned to support the continued growth and innovation of the automotive manufacturing industry.