Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 24, 2024 Visit:357 Source:Roll Forming Machine Factory

In the ever-evolving manufacturing landscape, roll forming machine manufacturers have recognized the growing importance of providing customized solutions to meet the diverse needs of their clients. This shift towards tailored offerings has not only enhanced the competitiveness of these manufacturers but has also significantly improved the satisfaction and loyalty of their customers.

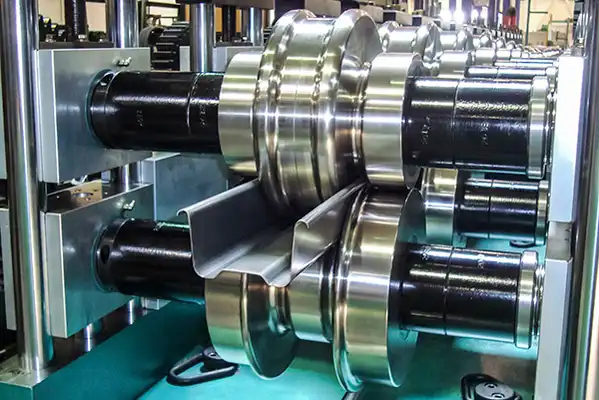

Customized roll forming machines are designed to meet specific requirements, rather than adhering to a one-size-fits-all approach. Manufacturers now work closely with their clients to understand their unique production needs, including the type of material being processed, the desired shape and size of the final product, and any specific performance criteria. This collaborative approach ensures that the roll forming machine is optimized for the specific application, maximizing efficiency and productivity.

One of the key benefits of customized solutions is the ability to accommodate unique material properties. Different metals and alloys have varying characteristics, such as tensile strength, ductility, and corrosion resistance. By designing roll forming machines that are tailored to the specific material being processed, manufacturers can ensure optimal forming conditions, reducing waste and enhancing product quality.

In addition to material considerations, customized roll forming machines can also be designed to meet specific production volumes and schedules. For example, a manufacturer producing high volumes of a single product may require a machine with high-speed capabilities and robust construction to ensure consistent output and longevity. Conversely, a manufacturer producing a wide range of products in smaller batches may require a more flexible machine that can be easily adapted to different forming processes.

Another critical aspect of customized solutions is the ability to incorporate specific features and functionalities. This could include automated feeding and cutting systems, integrated quality control mechanisms, or specialized tooling for complex shapes and profiles. By incorporating these features, roll forming machine manufacturers can provide their clients with turnkey solutions that streamline the production process, reduce labor costs, and enhance overall efficiency.

Moreover, customized roll forming machines can be designed to meet specific safety and regulatory requirements. In many industries, there are strict guidelines and standards that must be adhered to during the manufacturing process. By working closely with their clients, roll forming machine manufacturers can ensure that their machines comply with all relevant regulations, minimizing the risk of compliance issues and potential penalties.

The focus on customized solutions has also led to increased innovation and development within the roll forming machine industry. Manufacturers are continuously investing in research and development to explore new technologies and materials that can be incorporated into their machines. This ongoing innovation ensures that roll forming machines remain at the forefront of manufacturing technology, providing clients with the latest advancements and capabilities.

In conclusion, roll forming machine manufacturers have recognized the value of providing customized solutions to meet the diverse needs of their clients. By working closely with their customers, these manufacturers can design machines that are optimized for specific materials, production volumes, and features. This approach not only enhances the competitiveness of the manufacturers but also improves the satisfaction and loyalty of their clients, fostering long-term relationships and driving sustained growth.