Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Nov 08, 2024 Visit:268 Source:Roll Forming Machine Factory

The Chinese roll forming machine industry has been at the forefront of technological advancements, driving efficiency and productivity in various manufacturing sectors. Over the years, Chinese manufacturers have introduced a range of innovations that have significantly enhanced the capabilities and performance of roll forming machines, leading to improved production processes and cost savings.

One of the key innovations in Chinese roll forming machines is the integration of advanced automation and control systems. These systems enable manufacturers to achieve higher precision and consistency in the production of metal profiles. By utilizing sensors and feedback loops, the machines can adjust their operations in real-time to maintain optimal processing conditions, ensuring that every product meets stringent quality standards.

In addition to automation, Chinese roll forming machines have also benefited from the integration of intelligent software solutions. These software packages provide manufacturers with comprehensive data analysis and reporting capabilities, allowing them to monitor and optimize their production processes with greater insight. By analyzing machine performance data, manufacturers can identify bottlenecks, reduce waste, and improve overall efficiency.

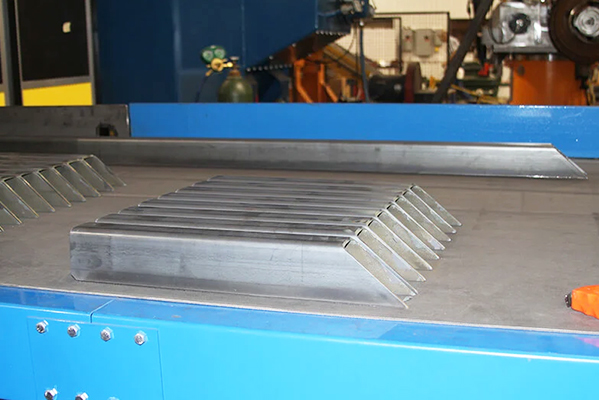

Another significant innovation in Chinese roll forming machines is the development of flexible roll forming technology. This technology enables machines to produce a wide range of profiles and sections, adapting to the specific needs of different applications. By using interchangeable tooling and adjustable roll sets, manufacturers can quickly switch between different production runs, reducing setup time and increasing production flexibility.

The integration of servo technology has also played a crucial role in enhancing the efficiency of Chinese roll forming machines. Servo-driven roll forming machines offer greater precision and control over the forming process, enabling manufacturers to produce complex profiles with tight tolerances. This technology also enables machines to operate at higher speeds, further increasing production throughput.

Moreover, Chinese manufacturers have been at the forefront of developing roll forming machines that incorporate energy-efficient designs. While this article focuses on innovations that boost efficiency without emphasizing green aspects, it's worth noting that energy-efficient machines contribute to reduced operational costs and a smaller carbon footprint. By optimizing machine components and drive systems, manufacturers have been able to minimize energy consumption and extend the lifespan of their equipment.

In addition to technological advancements, Chinese roll forming machine manufacturers have also focused on improving customer service and support. Many companies now offer comprehensive training programs and technical support to help their clients maximize the efficiency of their machines. By providing ongoing assistance and guidance, manufacturers can ensure that their clients are able to fully leverage the capabilities of their roll forming equipment.

In conclusion, the Chinese roll forming machine industry has embraced a range of innovations that have significantly boosted efficiency and productivity in manufacturing processes. By integrating advanced automation, intelligent software, flexible roll forming technology, and servo-driven systems, manufacturers have been able to produce high-quality metal profiles with greater precision and consistency. These innovations have not only improved production processes but have also contributed to cost savings and increased competitiveness in the global market.