Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 24, 2024 Visit:320 Source:Roll Forming Machine Factory

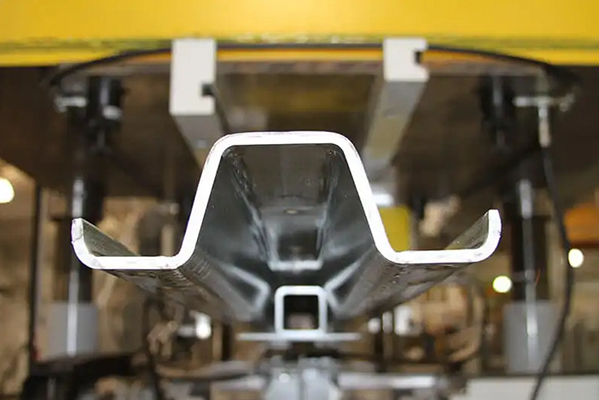

The global landscape of manufacturing is evolving rapidly, driven by a relentless pursuit of innovation, efficiency, and precision. Among the many advancements shaping this evolution, advanced cold forming machinery solutions have emerged as a cornerstone of modern production processes. The demand for these machines is steadily growing across industries, as they offer unparalleled advantages in terms of material utilization, cost-effectiveness, and product quality.

Cold forming, a process that involves shaping materials at room temperature without the need for heat treatment, has traditionally been a mainstay in metalworking. However, recent advancements in technology have pushed the boundaries of what is possible with cold forming machinery. These machines are now capable of handling a broader range of materials, including high-strength alloys and composite materials, with greater precision and repeatability than ever before.

One of the key drivers of the growing demand for advanced cold forming machinery is the automotive industry. As manufacturers strive to meet stringent fuel efficiency and emission standards, they are increasingly turning to cold forming to produce lighter, stronger, and more durable components. The ability to form complex shapes and geometries with high precision, while maintaining material integrity, is a significant advantage in this sector.

The aerospace industry is another major beneficiary of advanced cold forming machinery. Components in aircraft and spacecraft must meet rigorous standards for strength, durability, and weight reduction. Cold forming machines are capable of producing these components with exceptional accuracy and repeatability, ensuring that they meet the most demanding specifications.

In addition to these traditional industries, the demand for advanced cold forming machinery is also growing in sectors such as electronics, medical devices, and renewable energy. In electronics, cold forming machines are used to produce intricate components such as connectors and terminals, which require high precision and reliability. In the medical device industry, these machines are instrumental in the manufacturing of surgical instruments and implants, where precision and biocompatibility are paramount. In renewable energy, cold forming machinery is used to produce components for wind turbines, solar panels, and other energy-harvesting systems.

The growing demand for advanced cold forming machinery is also being fueled by the need for cost-effective manufacturing solutions. Cold forming is a highly efficient process that minimizes material waste and reduces the need for secondary operations such as machining and grinding. This results in significant cost savings for manufacturers, who can pass these savings on to consumers in the form of more affordable products.

Furthermore, the advent of smart manufacturing technologies, such as automation and data analytics, is enhancing the capabilities of cold forming machinery. These technologies enable manufacturers to optimize production processes, monitor machine performance, and predict maintenance needs, further increasing the efficiency and reliability of cold forming operations.

In conclusion, the global demand for advanced cold forming machinery solutions is growing steadily across a wide range of industries. These machines offer significant advantages in terms of material utilization, cost-effectiveness, and product quality, making them indispensable tools in modern manufacturing environments. As technological advancements continue to drive innovation, the potential applications of cold forming machinery will continue to expand, opening up new opportunities for manufacturers to create more efficient, sustainable, and competitive production processes.