Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 24, 2024 Visit:349 Source:Roll Forming Machine Factory

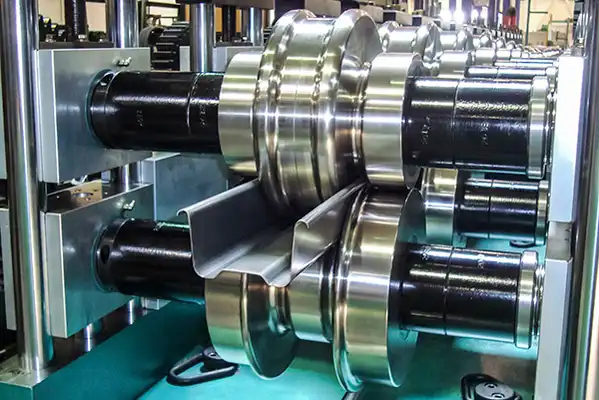

The manufacturing landscape is constantly evolving, driven by innovations that aim to improve efficiency, reduce costs, and enhance product quality. Among these advancements, the evolution of cold forming machine technology stands out as a pivotal force in streamlining manufacturing processes. Cold forming, a manufacturing technique that involves shaping metal without the use of heat, has seen significant technological enhancements that have transformed it into a more precise, efficient, and versatile process.

One of the most notable advancements in cold forming machine technology is the integration of advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These systems enable manufacturers to design and simulate the cold forming process with unprecedented accuracy. By utilizing CAD/CAM software, engineers can create detailed models of the desired product, analyze potential forming issues, and optimize the forming process before it even begins. This predictive capability reduces the need for trial and error, saving time and resources.

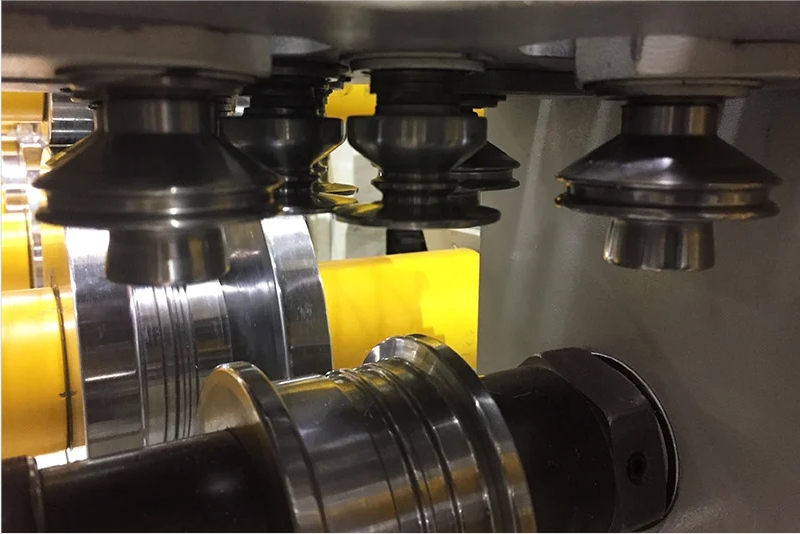

Another key technological advancement is the use of servo-electric drives in cold forming machines. Traditional hydraulic and pneumatic systems have been largely replaced by servo-electric drives, which offer greater precision, faster response times, and more consistent forming pressure. Servo-electric drives also enable manufacturers to implement closed-loop control systems, which monitor and adjust the forming process in real-time to ensure consistent product quality.

The advent of multi-axis cold forming machines has further streamlined manufacturing processes. These machines are capable of performing complex forming operations in a single setup, reducing the need for multiple machines and handling steps. Multi-axis machines also enable manufacturers to produce a wider range of products with greater flexibility, as they can be easily reconfigured to accommodate different forming requirements.

In addition to these technological advancements, cold forming machine manufacturers have also focused on improving the ergonomics and safety of their equipment. Modern cold forming machines are designed with operator-friendly controls and safety features, such as emergency stop buttons, interlocks, and pressure-sensing devices, to minimize the risk of injury. These improvements not only enhance operator safety but also contribute to a more efficient and productive manufacturing environment.

The benefits of these technological advancements are numerous. By streamlining manufacturing processes, cold forming machine technology enables manufacturers to produce high-quality products at a lower cost. The increased precision and consistency of the forming process reduce waste and defects, leading to higher yields and greater profitability. Furthermore, the flexibility and versatility of modern cold forming machines allow manufacturers to respond quickly to changes in market demand, enabling them to stay competitive in a rapidly evolving industry.

In conclusion, the advancements in cold forming machine technology have had a profound impact on manufacturing processes. By integrating CAD/CAM systems, implementing servo-electric drives, developing multi-axis machines, and improving ergonomics and safety, manufacturers have been able to streamline their operations, enhance product quality, and reduce costs. As technology continues to evolve, it is likely that we will see even more innovations in cold forming machine technology, further transforming the manufacturing landscape.