Navigation Menu

Contact Us

- Email:

- info@wxavatar.com

- Address:

- Yurong Village, Yuqi Street, Huishan District, Wuxi, China.

Release Date:Oct 24, 2024 Visit:379 Source:Roll Forming Machine Factory

In the ever-evolving world of manufacturing, Chinese roll forming machine manufacturers have consistently demonstrated their prowess in delivering innovative solutions tailored to meet the diverse needs of industries across the globe. By integrating cutting-edge technology and advanced design principles, these manufacturers have crafted machinery that not only enhances productivity but also ensures precision and reliability in metal forming processes.

The manufacturing sector, spanning from automotive to aerospace, construction to electronics, demands a wide array of metal profiles for various applications. Chinese roll forming machines have adapted to these diverse requirements, offering flexibility and versatility that cater to the specific needs of each industry. Whether it's forming intricate details on automotive body panels or creating structural beams for large-scale construction projects, Chinese machinery has proven its mettle in delivering consistent quality.

One of the key innovations in Chinese roll forming machines lies in their advanced automation capabilities. Manufacturers have integrated intelligent control systems that allow for precise adjustments during the forming process, ensuring that each product meets stringent tolerance levels. These systems not only enhance accuracy but also improve overall efficiency by minimizing manual intervention and setup time.

Moreover, Chinese roll forming machines are designed with modularity in mind. This feature allows manufacturers to easily configure and reconfigure the machines to produce different profiles, adapting to changes in product demands or market trends. Modularity also facilitates easier maintenance and upgrades, ensuring that the machines remain up-to-date with the latest technological advancements.

In terms of material handling, Chinese roll forming machines have also made significant strides. They are equipped with robust feeding and conveying systems that can handle a variety of metal thicknesses and widths, making them versatile for use with different materials. This adaptability is crucial for manufacturers who work with a range of metals, from mild steel to aluminum and stainless steel.

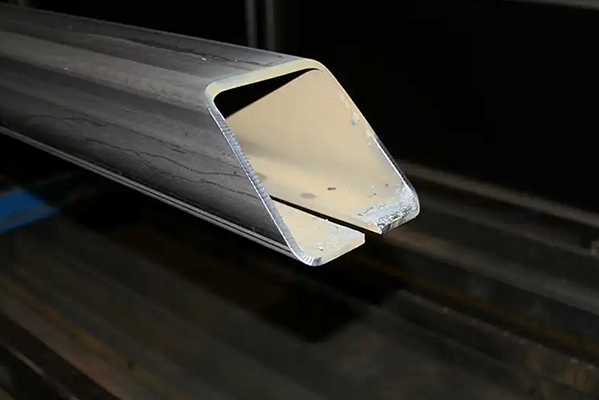

The versatility of Chinese roll forming machines extends to their ability to produce complex shapes and profiles. Through the use of advanced roller designs and forming techniques, these machines can create intricate geometries that would be difficult or impossible to achieve with traditional methods. This capability is particularly valuable in industries like aerospace and electronics, where precision and complexity are paramount.

Chinese manufacturers have also focused on enhancing the user experience of their roll forming machines. They have incorporated user-friendly interfaces and intuitive control panels that make it easier for operators to monitor and adjust machine settings. This attention to ergonomics and usability not only boosts productivity but also reduces the risk of operator error, ensuring consistent quality in the final product.

As industries continue to evolve and manufacturing demands become more complex, Chinese roll forming machine manufacturers remain committed to innovation. They are actively investing in research and development, exploring new technologies and materials that can further enhance the capabilities of their machines. This relentless pursuit of excellence ensures that Chinese roll forming machines will continue to address the diverse needs of manufacturers worldwide.

In summary, Chinese roll forming machine innovations have transformed the landscape of metal forming, offering solutions that cater to the wide-ranging requirements of various industries. With their advanced automation, modularity, material handling capabilities, and user-centric designs, these machines are poised to remain a cornerstone of manufacturing excellence for years to come.